Tractor Plants has chosen Cortona3D solutions for creating maintenance documentation

The Tractor Plants Concern, one of the largest machinery industrial groups in Russia, has chosen Cortona3D solutions for creating modern product support documentation

The Tractor Plants Concern consolidates more than twenty large companies in Russia and abroad, its dealer network has 130 partner companies and 50 service centers. The company is strategically focused on growing its leadership in the Russian market of light and heavy mechanical engineering and on increasing its sales in international markets.

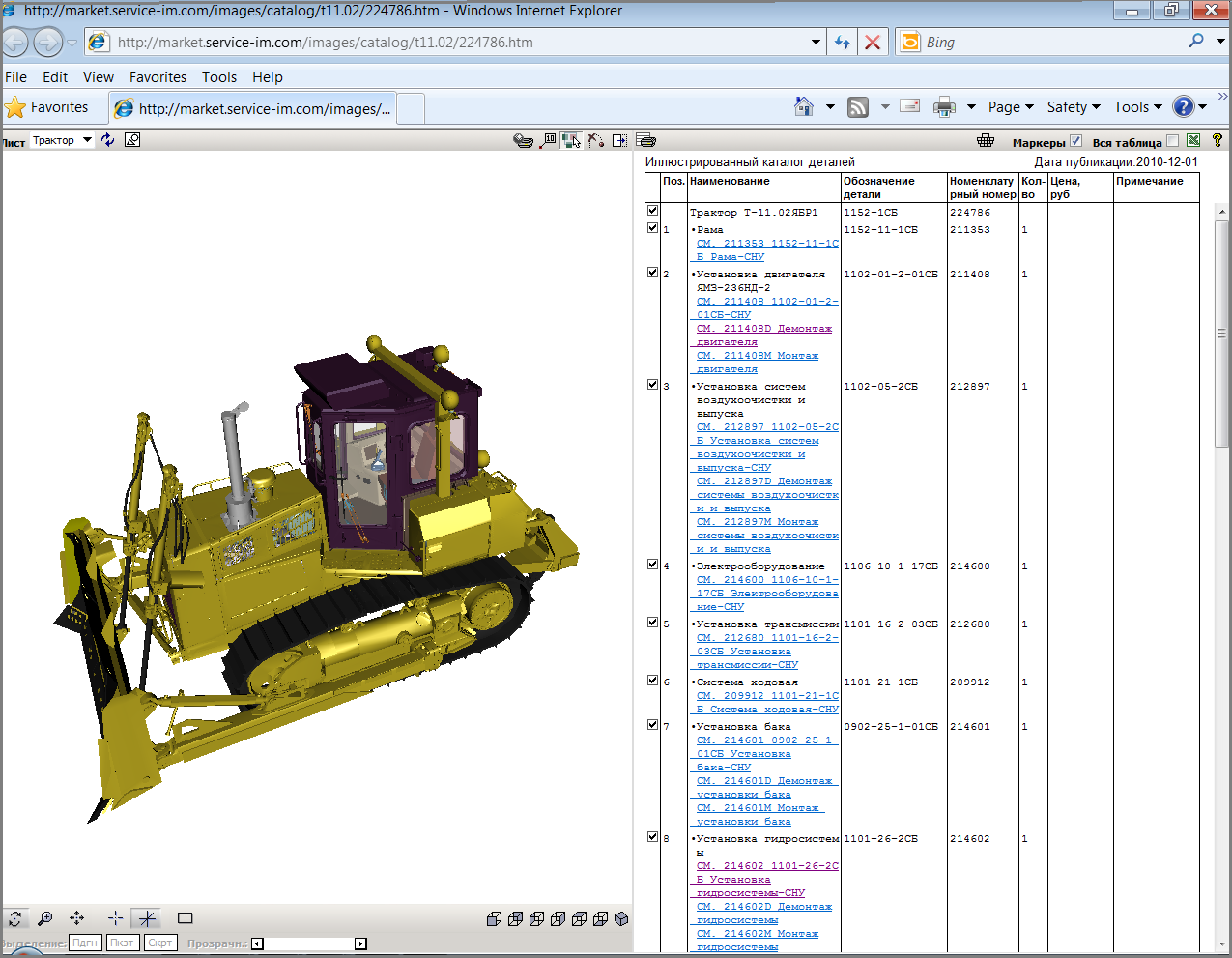

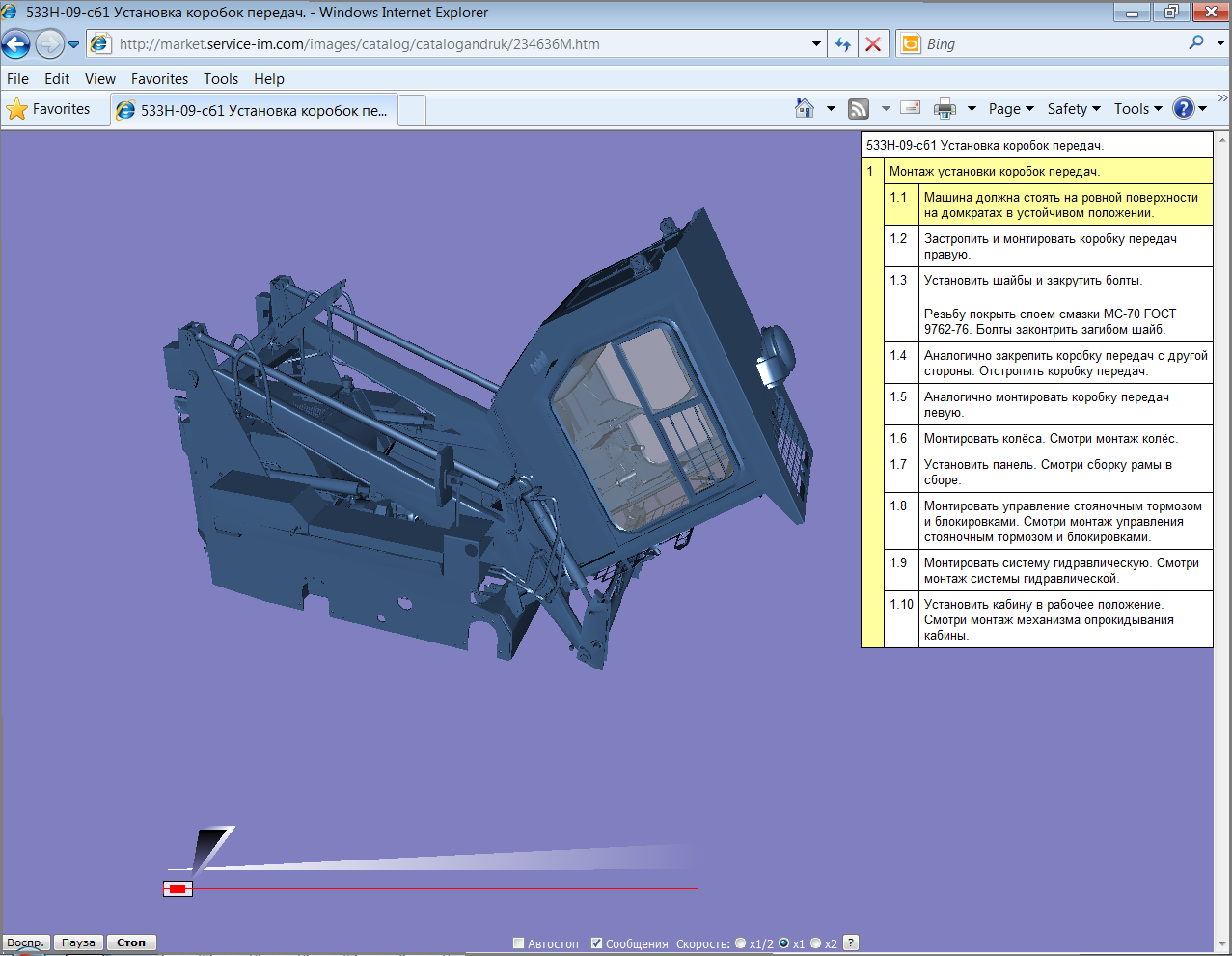

The availability of high-quality maintenance documentation is one of the essential factors to ensure the successful usage of company products. Tractor Plants has chosen Cortona3D solutions for creating maintenance documentation – parts catalogs and technical manuals for assembly and disassembly procedures.

Cortona3D solutions benefits

- Significant decrease of documentation production timelines and costs due to the usage of existing CAD/PDM data and integrated environment for authoring 2D and 3D graphics and textual descriptions

- Documentation creating process is easy and intuitive, the product is visually represented in the final document

- Ability to promptly update documentation and deliver updates to service companies and dealers over the Internet

Implementation of Cortona3D solutions

Implementation of new technology started with a 5-day introductory training. After the training, the team of authors began creating parts catalogs and maintenance manuals using RapidCatalog and RapidManual. Real engineering data (SE, CATIA, NX, JT, Solidworks, and others) were used as the source data. Cortona3D solution allowed to preserve all useful information during the import process, 3D objects were automatically linked to the DPL table (bill of materials).

First innovative 3D and 2D documentation kits have been created for the products of several companies such as:

- Harvester Yenisei - 950

- Multipurpose construction and community services machine MKSM-800

- Agricultural tractor AGROMASH-90TG

- AMZ engines

- Industrial bulldozer Т-11.02

Created documentation is placed on the company website. This allows for rapid access of service companies and dealers to up-to-date documents.

Producing a documentation kit for a single model takes much less time for now and as a result, the team of authors exceeded the plan for the first year. We also received highly positive reviews from service companies regarding the quality of documentation and plan to extend a list of models with documentation of the new generation. As the next step, we will create an integrated web portal for service companies.

Evgeniy GavrilovInformation Technology Department Manager, Tractor Plants

RapidCatalog benefits

- Automated cross-referencing of CAD data and BOM during the import process provides the possibility to easily create 3D/2D interactive catalogs of high quality

- Ability to customize the catalog appearance and content (DPL table content and other) according to the customer requirements

- Automatic generation of 2D images based on 3D views. Automatic generation of links between 2D image callouts and active DPL rows

- Parts catalog can be integrated into an ordering system, maintenance manuals or exported to Excel

- Ability to create a PDF version of the illustrated parts catalog

RapidManual Benefits

- An integrated environment for creating and authoring 3D and 2D graphics and text

- A library of simple animation actions such as: ‘rotate’, ‘detach’, etc. provides the possibility to easily create the required sequence of steps

- Using maintenance manual developed in RapidManual in conjunction with the corresponding parts catalog developed in RapidCatalog allows for rapid ordering of parts necessary for repair and other procedures

The Tractor Plants Concern is one of the major Russian integrators of scientific and technical, production, and technological and financial resources in the engineering industry.

Main product lines: industrial machinery, agricultural machinery, spare parts, OEM components, railway products, special machinery.

The company supports the full product life cycle – from research and development activities, metal and spare parts production to marketing and sales operations, after-sales maintenance, and customer support.

- RapidCatalog

- RapidManual

- Until recently the company used highly time-consuming and labor-intensive paper documentation

- The quality of product support documentation didn’t meet the current demands

- There was a strong need for a new solution to greatly enhance the documentation quality, speed time to market, and reduce update time

The Tractor Plants Concern has explored several software products and chosen RapidCatalog and RapidManual developed by Cortona3D. This software enables quick and easy creation of interactive 2D/3D documentation based on existing CAD data.

- Reduction of time required to create and update documentation

- Dramatic decrease of errors when choosing and ordering spare parts

- Reduction of time required to learn complicated procedures

- Integrated web portal for service companies and dealers