KAMAZ has implemented Cortona3D solutions for creating 3D interactive maintenance documentation

KAMAZ Group of Companies has implemented Cortona3D solutions for creating 3D interactive maintenance documentation

KAMAZ Group of Companies is the largest automotive corporation in Russia. The integrated manufacturing complex covers the full technological cycle of truck production – from design, manufacturing, assembly of vehicles, and auto parts to sales and service maintenance.

Modern automotive companies get a growing part of their profit from service, and the customers’ demands for after-sales support are increasing. KAMAZ puts a great emphasis on updating its dealer network, developing after-sales services, and improving maintenance documentation.

KAMAZ scientific and technical center researched many software products for creating maintenance documentation. The center selected the Cortona3D solution as it can be fully embedded in the development process of all kinds of product documentation. This becomes possible due to Cortona3D integration with Teamcenter PLM software, which was earlier implemented at KAMAZ. Combining data from design, technology, and maintenance documentation allow for creating relevant documentation that corresponds to vehicle design and actual structure.

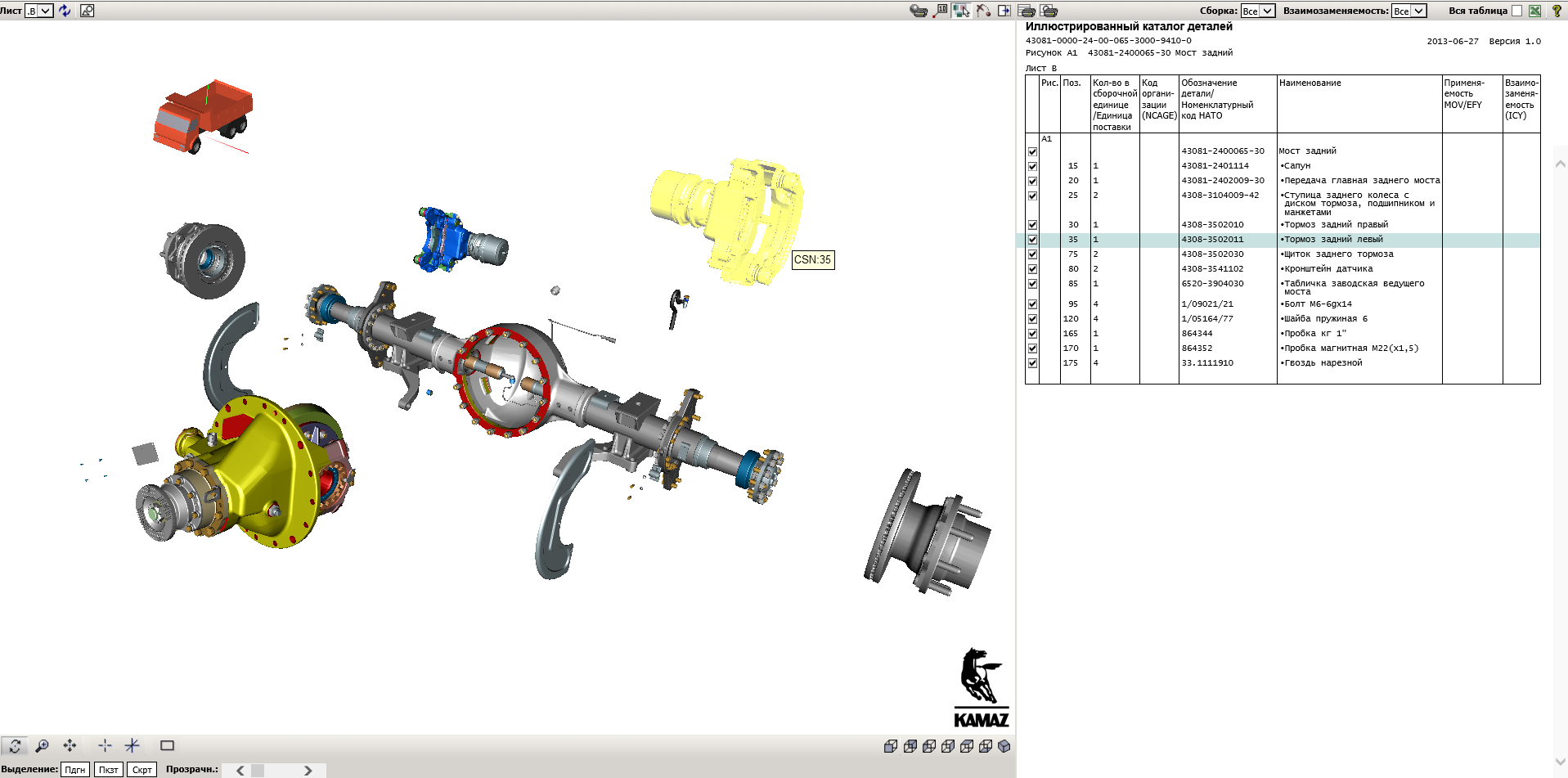

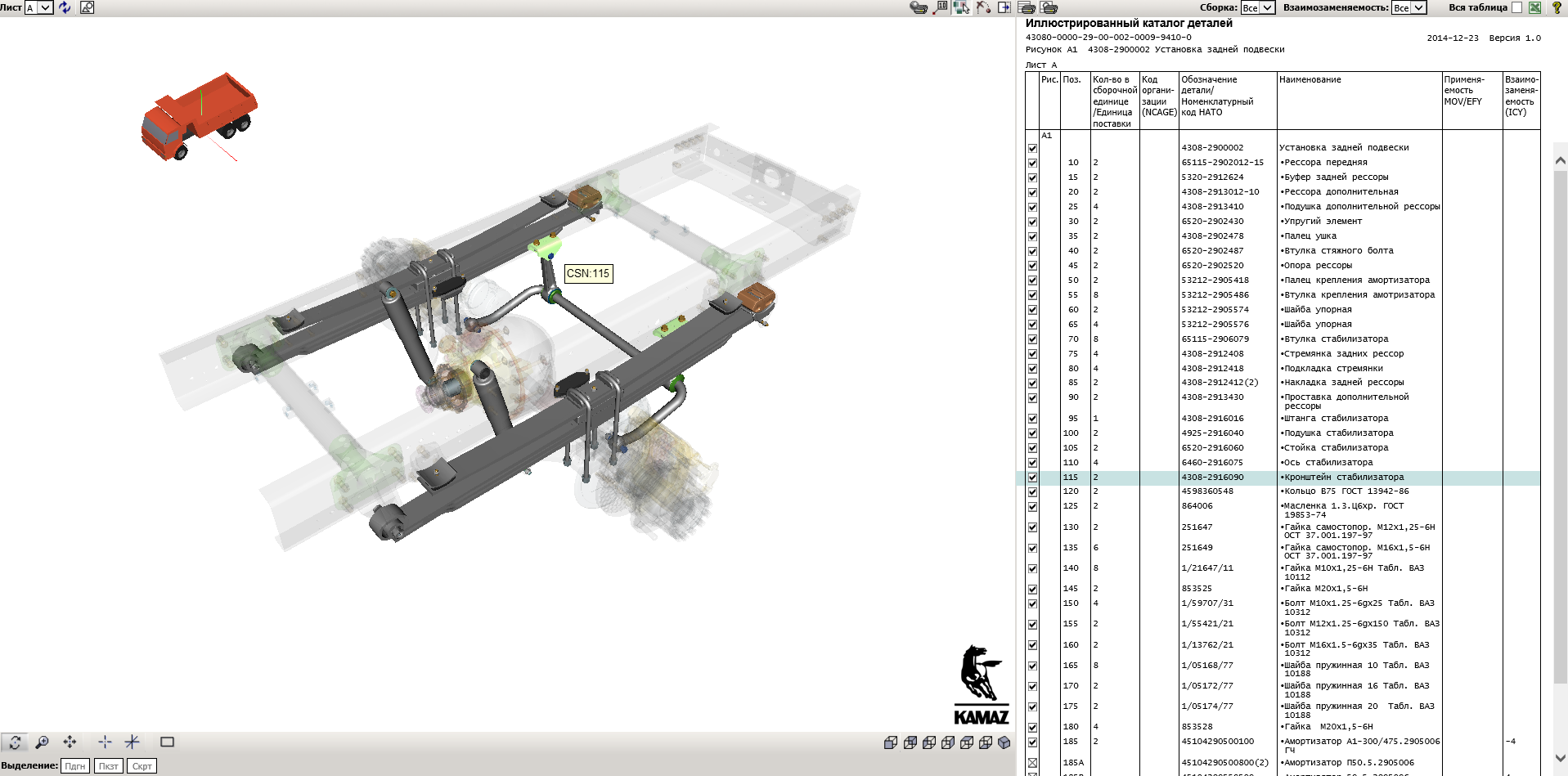

Parts catalogs development

Implementation of Cortona3D software started with parts catalogs as they are considered the most important type of maintenance documentation. Parts catalog for KAMAZ-5308 was developed within a pilot project and full-scale implementation of Cortona3D software was launched afterward. Within a month, a group of experts from the technical documentation design department was trained to work with the new software.

Documentation creation process

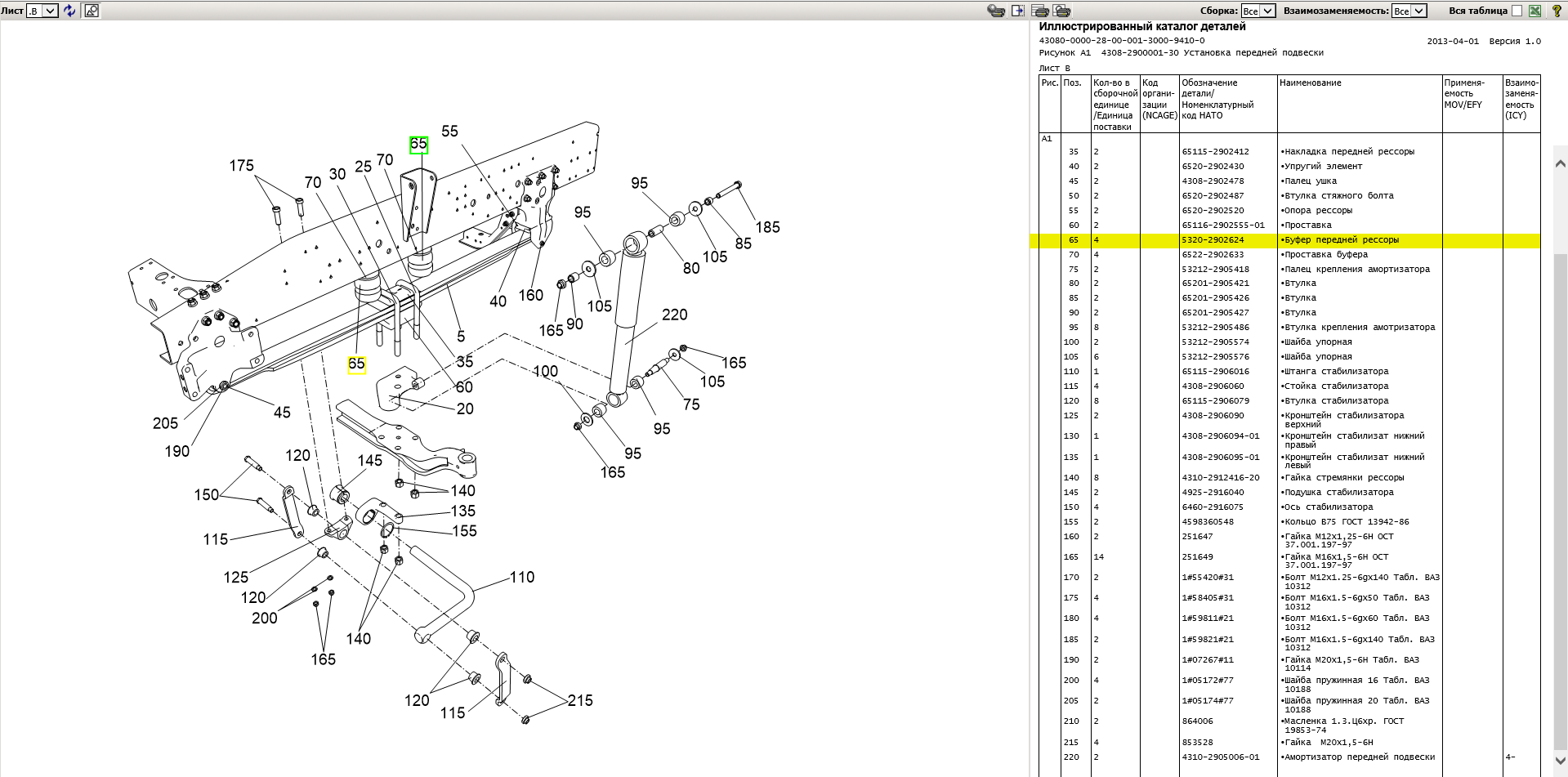

Digital layout technology, 3D modeling, and the Teamcenter update process were introduced at KAMAZ earlier, when NXTM software and Teamcenter PLM solutions were implemented. An integrated design and manufacturing process was established then, and Cortona3D solutions have contributed to this process. RapidAuthor imports existing design data and match the bill of materials with CAD data. 3D exploded views are created with the help of intuitive Explode Wizard. 2D images and callouts are generated automatically. The final document can be stored as an interactive 3D/2D web document or as a printable 2D PDF file.

In the past, considerable time was spent creating a layout for final documents and updating paper documentation. The update process is much faster now with 3D modeling and Cortona3D solutions implemented at KAMAZ.

Flexible approach to creating documentation for different generation models

RapidAuthor is also used to create maintenance documentation for previous-generation vehicle models that were designed in 2D. Existing 2D graphics are modified with the help of Cortona2D Editor Pro, one of the RapidAuthor components. The full range of RapidAuthor features is used to create documentation for newer vehicle models designed in 3D.

Results and prospects

Since 2015, all parts catalogs for KAMAZ products have been created with RapidAuthor. 3D catalogs are available at the KAMAZ digital maintenance documentation portal for dealers. There are a lot of positive reviews of the new documentation. Previously, service center employees had to master very specific skills to work with traditional parts catalogs, as most of the 2D illustrations were adapted engineering drawings. 3D catalogs are more intuitive and enable easy comparison of 3D model parts with actual parts to be replaced.

The time required to create technical documentation for new models designed in modern CAD and PLM systems has decreased by 40%. Update time has decreased by 90%. Outdated information is unlikely to occur in the maintenance documents due to the link with existing CAD/BOM data.

Cortona3D technology for creating interactive 3D procedures for maintenance operations and descriptive data modules is being tested now. It is also planned to enable dealers to use 3D catalogs and procedures on mobile devices, user requirements are being gathered and analyzed at the moment.

We have a qualitative change in the new way we provide information about maintenance and repairing of KAMAZ products, their structures, and spare parts. Positive reviews show we are going in the right direction.

Irek GumerovDeputy general director, KAMAZ

KAMAZ Group of Companies is in the top twenty world's leading manufacturers of heavy-duty trucks. More than 2 million vehicles have been made since 1976 when the first truck rolled off the production line. The company commands more than 50% of the Russian heavy-duty truck market share. In the KAMAZ divisions and subsidiaries work about 40000 employees.

- RapidAuthor S

- Teamcenter Connector

- Rapid Developer

- Paper maintenance documentation production and update process are highly time-consuming and labor-intensive

- New tools are required to greatly enhance documentation quality, speed time to market, and reduce update time

- The time required to create maintenance documentation for new models decreases by 40%

- The update time for maintenance and repair documentation decreases by 90%

- Maintenance and repair documentation is in compliance with engineering data